Modular MDR Conveyor

Modular MDR Conveyor

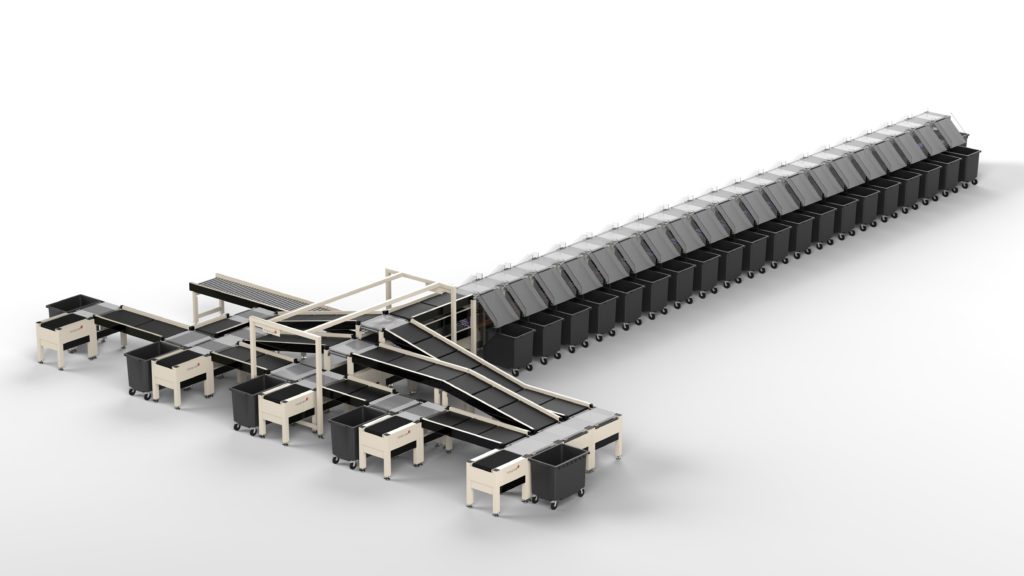

eSort Conveyor developed our modular MDR conveyor specifically for Omni channel Order fulfillment, receiving and reverse logistics. This MDR has distributed network controls that substantially reduce engineering timelines and installation schedules by utilizing next generation encoded rollers and control cards that are simple to program, implement and manage.

eSort Conveyor developed our modular MDR conveyor specifically for Omni channel Order fulfillment, receiving and reverse logistics. This MDR has distributed network controls that substantially reduce engineering timelines and installation schedules by utilizing next generation encoded rollers and control cards that are simple to program, implement and manage.

eSprt Conveyor controls allow for easy configuration and implementation, all conveyors including sorters are run off an Ethernet Network.

eSort SENERGY ROLLER

eSort Senergy roller has a unique gearbox design and powerful brushless DC motor that provides an extremely efficient means of delivering an amazing amount of torque and speed with the smallest amount of energy. Typically used in conveyors for Zero Pressure Accumulation or roller transportation.

eSort Senergy gearbox selection contains only 11 gearbox combinations to make ordering a breeze and inventory much more manageable. Senergy’s range and performance characteristics are rated for speeds between 6 to 969fpm and starting torque up to an amazing 215 in/lbs.

High Torque

DC brushless motor provides much higher running torque compared to the same size AC motor which enables the eSort Senergy roller to handle heavier loads or reduce the required number of Motor Rollers.

Dynamic brake

DC brushless motor provides electrical brake method called Dynamic brake or Regenerative brake.

This feature provides instantaneous stop unless the product slips over the tube surface, thus there are no mechanical brake device or pneumatic cylinder are required for many cases.

Wide speed range

DC brushless motor provides wide speed range (e.g. SENERGY, Speed code 35 – Eco mode, diameter 50.0 mm provides from 5.0 to 49.8 m/min) and speed can be selected by the driver card setting.

Functionality and Logic control

eSorts’ cutting-edge controls provide useful functions, not only dynamic brake or variable speed, but also constant speed control (maintaining running speed regardless of load conditions), Acceleration & Deceleration timer setting, etc…

Intelligent Accumulation and eSort control cards provide advanced system functions for features such as ZPA (Zero Pressure Accumulation) while dramatically reducing wiring and PLC programming.

eSort MDR Conveyor Suits Any Application

Advanced Networked Controls

eSort control cards provide many innovative -standard- features for

Zero Pressure Accumulation or applications utilizing low voltage brushless motors. The card controls 2 motor drives in Zero Pressure Accumulation mode. Integrator’s that use PLC or PC controls for MDR systems can take advantage of the Ethernet communications which connects to any major PLC brand for complete control of eSort Control cards. eSort’s ConveyLogix program transforms the control cards into a fully functional PLC with ladder logic, function block or script with the ability to control sorters, diverts, transfers and merges.

Features

- Ethernet I/P, Modbus/TCP, PROFINET Connectivity

- Baud rate: 10Mbps / 100Mbps

- 2 Zones control (Up to 4 sensors and 2 motors connections)

- Both NPN/PNP photo-eye sensor applicable

- One push button Auto-Configuration

- ZPA (Zero Pressure Accumulation) logic; Singulation, Train and Gap Train

- EasyRoll™l Software for changing default configuration and customizing functionality of each module

- Motor error detection (Overload, Over-current, motor not connected)

- Jam error detection (Sensor Jam, Arrival Jam)

- Mechanical brake control

Ready to Run On-Site

- PLC- or PC-based control or platform

- eSort Control cards include pre-assigned IP addresses for each zone and all cards / zones can be easily re-named from a laptop across the system

- All conveyor sections and sorters pre-wired with eSort control cards for Ethernet Network controls communications

- All conveyor sections and sorters pre-wired with Electrical for 24v DC Power distribution and simple outlet plug in or other electrical drop.

- All linear beds of conveyor: transportation, inclines, declines and curves include ready to run ZPA available automatically at start up. (no programming required)

- Only One 24 Volt DC Photo Eye per Zone required with encoded rollers

Conveyor Hardware Details

- Frame: 6.5” x 2” x 12 Ga. formed steel channel frame

- Brushless DC motors

- Rollers: 1.9 Diameter, 16ga. rollers, with 7/16” hex axle.

- Roller Centers: Rollers are mounted low in frame on 3” roll centers

- ABEC roller bearings, grease sealed bearings

- One 24 Volt DC drive rollers per accumulation zone

- One 24 Volt DC control card per two accumulation zones

- Smoked lexan side covers (over trough) on wiring side only, wiring not visible

- Drive bands: 3/16” * 83A high strength urethane O-belts

eSort Conveyor provides innovative, next generation box openers, e-sorters and state-of-the-art conveying technology. Contact us today to learn more about our truly modular, plug in and run, MDR conveyor solutions.